» RAILWAY

Solutions for RAILWAY

For years, Mäder Group companies have produced paint to protect and decorate railways vehicles. As world leader for railways paint, the Mäder Group has a wide range of solutions :

- Passenger carriage interiors : Decoration solutions for passenger carriage interiors

- Bogies and Axles : Anti-corrosion and mechanical protection technology

- Resins and gelcoats for Composites : Innovative technology combining efficient Fire/Smoke performance with ease of implementation

- Anti-graffiti solutions : Solutions for cleaning off and protecting against graffiti

- Wagon construction : solutions to protect goods wagons

- Technical products for structures : Technical products tailored to the basic protection of body structures and specific protection applications

- Cleaning and preparation of surfaces : Surface cleaning and preparation solutions

- Services : Services linked to painting activities

» CRYSTAL CAR PLUS

Cristal Car Plus is a fast curing one component MS-polymer® adhesive highly viscous and thixotropic.

It is recommended for windscreen replacement ensuring safety and good performance on all types of vehicles.

Cristal Car Plus cures in a short time allowing removal of the vehicle in 1 hour after installation.

May be applied on ceramic coated glass without need of primer.

Cristal Car Plus is non conductive and recommended for use on front and rear windshield with integrated aerials for radio, TV and satellite receiving systems (GSM).

» VITROFIX KIT

Composed by:

• 1 adhesive Vitrofix in 310 ml cartridge

• 1 cleaner in 30 ml bottle

• 1 primer in 30 ml bottle

• 1 metal thread

• 1 rod for primer application

• 1 woven no woven napkin for cleaner

• 1 standard nozzle + 1 special nozzle (with nail)

Colour : Black

» 177 NEOPRENIC ADHESIVE

177 is an adhesive semi-fluid to the touch, suitable for bonding rubber, natural leather, simulated leather and cloth, felt, expanded polyurethane on painted panel, etc.

Its specific application is bonding interior head liners and trim areas.

Is high temperature resistant and therefore suggested in the body-shop for bonding vehicle roof top areas.

It shows high performance level and dries quickly.

» MULTI SEAL

Multiseal is a high quality, non discolouring, elastic one component construction joint sealant.

MS Polymer® based, free from isocyanate, silicone and polyurethane. V.O.C. free.

Main characteristics are:

• excellent adhesion on many surfaces

• permanently elastic after curing

• Odourless

• can be painted immediately or within 48 hours after application

• excellent weather resistance

• resistance to many chemicals Multiseal has been studied for sealing of metal joints, fenders, doors, hoods, engine compartments, trunks, etc.

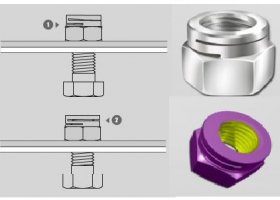

» SLOTTED SELF-LOCKING NUT

The principle of the self-locking nut ESL is to effect a locking on the sides of some threads of the male element on 2 sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values.

During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

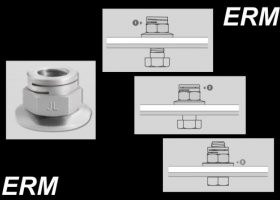

» SLOTTED SELF-LOCKING HEXAGON FLANGE NUT WITH FREE WASHER - ERM

The principle of the self-locking nut ERM is to effect a locking on the sides of some threads of the male element on 2 sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values.

During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

The ERM also includes a mobile conical washer which is flattened when assembling through the tension of the male element, under the effect of tightening torque. When phenomena causing a decrease of the tension of the male element, the conical washer is going to give back its own constraint which helps to maintain bolt tension under the most severe conditions.

Recommended for all electrical or security assemblies(case assemblies with multiple parts, stacked assemblies with toothings or racks, assemblies of parts consisting of metals at low hardness or soft materials, assemblies painted, electrical connections, etc.).

» SELF-LOCKING NUT BY DEFORMATION SRF STARNUTS

The principle of the self-locking nut SRF is obtained by deformation of the last nut thread by a 3 or 4 point indentation under a specific load.

During assembly, the screw is subjected to a pressure on the thread of the male element in contact with the distorted nut thread, creating a constant locking torque independent of preload.

The nut SRF has a fixed base providing greater contact surface with the support member providing a broader recovery efforts diffusion.

It can replace the washer under the nut affixed.

» SELF-LOCKING NUT BY DEFORMATION GSL ISO 7042

The principle of the self-locking nut GSL is obtained by deformation of the last nut thread by a 3 or 4 point indentation on the top of the nut under a specific load.

During assembly, the screw is subjected to a pressure on the thread of the male element in contact with the distorted nut thread, creating a constant locking torque independent of preload.

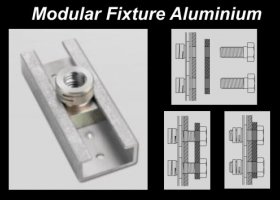

» MODULAR FIXTURES ALUMINIUM

Modular fixtures consist of stainless steel or light alloy channel, in which are mounted self-locking nuts or threaded studs positioned at predetermined distances. Regarding the screws the unloosening of the fasteners is due to the use of self-locking nuts.

Self-locking nuts have a square or rectangular section which is immobilized within the rail and a flange with 2 slots. The principle of the self-locking nuts is to effect on the sides of some threads of the male element on two sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values. During the assembly, the nut returns to its original form generating pressure on the threads which creates a constant locking torque independent of preload.

Modular fixtures allow to quickly report on an overall various fixing points pre-positioned with a certain cross freedom.

Modular fixtures allow for streamlined production and installation of panels, composites, doors and anywhere else. A self- locking adjustable nut is required in single or series.

They easily overcome any differences in critical tolerances when integrating various components.

Costly drill & tap operations are eliminated.

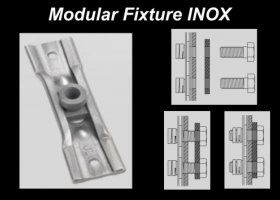

» MODULAR FIXTURES INOX

Modular fixtures consist of stainless steel or light alloy channel, in which are mounted self-locking nuts or threaded studs positioned at predetermined distances. Regarding the screws the unloosening of the fasteners is due to the use of self-locking nuts.

Self-locking nuts have a square or rectangular section which is immobilized within the rail and a flange with 2 slots. The principle of the self-locking nuts is to effect on the sides of some threads of the male element on two sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values. During the assembly, the nut returns to its original form generating pressure on the threads which creates a constant locking torque independent of preload.

Modular fixtures allow to quickly report on an overall various fixing points pre-positioned with a certain cross freedom.

Modular fixtures allow for streamlined production and installation of panels, composites, doors and anywhere else. A self- locking adjustable nut is required in single or series.

They easily overcome any differences in critical tolerances when integrating various components.

Costly drill & tap operations are eliminated.

» NYLON INSERT NUT EUM

The principle of the self-locking nut EUM is a is to crimp a nylon ring at the top of the nut during installation so that the ring deforms around the threads.

The EUM nut also includes a mobile conical washer on its base, which is flattened by the tension of the male element when assembling, under the tightening torque. When phenomena tend to decrease the initial tension of the male element, the conical washer will give back its own compressive constraint and maintain a the tension.

Recommended for all electrical or security assemblies(case assemblies with multiple parts, stacked assemblies with toothings or racks, assemblies of parts consisting of metals at low hardness or soft materials, assemblies painted, electrical connections, etc.).

» NYLON INSERT NUT HMP

The principle of the self-locking nut HMP is to crimp a nylon ring at the top of the nut during installation so that the ring deforms around the threads.

Temperature of the ring (to -40 ° C to + 230 ° C peak temperature).

Very low dispersion of the locking torque and constant quality.

» NYLON INSERT NUT HUP

The principle of the self-locking nut HUP is to crimp a nylon ring at the top of the nut during installation so that the ring deforms around the threads.

Temperature of the ring (to -40 ° C to + 230 ° C peak temperature).

Very low dispersion of the locking torque and constant quality.

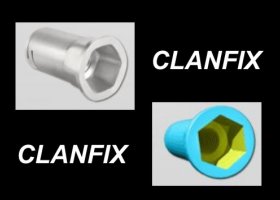

» OTHER PRODUCTS - CLANFIX

The nut CLANFIX is composed of a cylindrical shank and a hex-head ensuring no rotation once installed .

This nut has a triple function: nut, self-locking assembly and rivet assembly.

The CLANFIX functions as a thread on sheet metal with a minimum thickness of 1mm. Suitable for use on all metal and construction of certain composite constructions.

Installation is done blind (access one side). The principle of the self-locking nut CLANFIX is to effect a locking on the sides of some threads of the male element on 2 sectors, located in different planes and offset 180 °.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values. During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

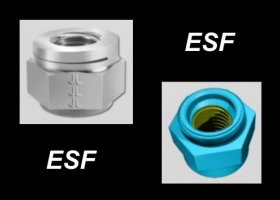

» OTHER PRODUCTS - ESF

The rivet nut ESF should be used to provide threads on sheet metal with thicknesses of 1mm or more. Suitable for use on all metal and construction of certain composite constructions.

The principle of the self-locking nut crimping ESF is to effect a locking on the sides of some threads of the male element on 2 sectors. The plan of the slot is perpendicular of the internal thread axis of the nut.

This principle is obtained by depitching two locking slots in the collar portion of the nut using precise values.

During assembly, the collar of the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload.

» SCP 27 RAIL

VABER SCP 27 RAIL is a water based sprayable coating designed to dampen noise from metal vibration in passengers wagons, floors, engine or equipment rooms, air duct.

Applied on vibrating area at a thickness ranging from 1,5 to 4 mm (dry film).

Vaber SCP 27 RAIL rapidly dries on surface and after 7-14 days in all its thickness.

Once hardened VABER SCP 27 RAIL shows excellent sound damping properties and stone chip resistance, has excellent adhesion on bare and painted metal and good resistance to outdoor climates.

It can be applied in thick vertical layers without sagging or dripping.

For technical dates refer to technical data sheet.

VABER SCP 27 RAIL is fire resistance CEN TS 45545-2 approval (on going Certification according American Standard NFPA 130 and British Standard BS 6853)

VABER SCP 27 RAIL is applied as internal coating or on exterior floors of the carriage to reduce noise from vibrating metal in a wide range of vibrating frequencies.

VABER SCP 27 RAIL is recommended for use on external parts without the need of a protective paint.

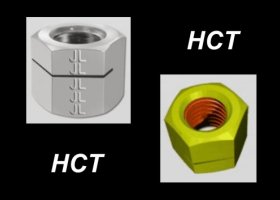

» OTHER TYPE OF SLOTTED SELF LOCKING NUTS - HCT

The principle of the self-locking nut HCT is to effect a locking on the sides of some threads of the male member on a sector of this latter.

This principle is obtained by performing 1 calibrated slot in the central portion the hex nut, which is then crushed under a specific load.

During assembly, the nut returns to the original form generating pressure on the threads which creates a constant locking torque independent of preload

» FIX&GO

FIX&GO is a polyurethane two component adhesive designed to repair, bond and reinforce plastic materials. It’s available in two speed version: 1-2 minutes and 5-7 minutes.

In car repair body shops, FIX &GO is recommended to repair and reinforce damaged bumpers, bonding of mechanical supports, logos, moldings, and for general fixing of plastic elements.

FIX&GO is easy to use: it’s low viscosity makes it easy to do fast repair without sagging even when applied in thick layer. Once hardened it is tough and sandable in few minutes; at low temperatures it still shows a certain degree of elasticity.

» CRISTAL CAR

CRISTAL CAR is a one component MS-Polymer adhesive, that cures with air humidity.

CRISTAL CAR is used for bonding and repair of windscreens and glasses on several vehicles. The curing speed is dependent from air humidity and temperature.

It is free from solvent and isocyanates, not flammable and shows very good elastic properties and resistance to ageing.

CRISTAL CAR may be used on serigraphed windscreens withoutthe need of black primer.

» VITROFIX

VITROFIX is a one component fast set polyurethane adhesive sealant recommended for automotive direct glazing.

VITROFIX cures in a short time allowing for removal of vehicle after 3 hours at 23°C and 50% relative humidity (passes FMVSS212)

» MULTIBOND

MULTIBOND is a one component MS Polymer based adhesive sealant with excellent mechanical and adhesive properties designed for the assembly of industrial construction elements and for sealing of concrete, metal and plastic joints where long lasting high mechanical properties are required.

Its characteristics are:

- Rapid and high green strength

- Permanently elastic and tough in short time

- Resists to thermal peaks ( max 30 min at 180°C)

- Odorless, solvent and isocyanate free

- Paintable after skin formation with most common paints

- Resists to mild chemical agents

- Excellent resistance to weathering agents, sun rays , will not turn to yellow

MULTIBOND is used for:

- Sealing different materials in industrial carpentry and car after market

- Bonding of non weldable materials ( i.e. metal profiles)

- Bonding of metal reinforcements on metal surfaces

- Assembly of metal and synthetic or plastic materials

» CRYSTAL CAR XP

MS Polymer® adhesive for bonding windscreen, external parts, metal parts, metal support, GRP parts.

Excellent resistance to UV-Wheathering conditions, high strength, high resistance features.

» PRIMER 1000

PRIMER 1000 is a fast drying wash primer designed for improving adhesion on different surfaces of MS-Polymer or SPUR adhesives and sealants.

PRIMER 1000 is especially recommended on:

- Glass Reinforced Polyester Resin (GRP)

- GRP coated with Gel Coat

- Galvanized or bare aluminium

- Painted metals

- Powder painted or lacquered metals (ie test trial is strongly recommended)

- Bare metal, stainless steel, copper and brass

- ABS

- Rigid PVC

- BY BLEND

» PRIMER VITROFIX

PRIMER VITROFIX is a polyurethane black primer to improve adhesion of Vitrofix adhesive on glass

Primer Vitrofix is also used in direct glazing to shield and protect adhesive from the most damaging component of UV rays.

It is also used to improve adhesion of polyurethane on other materials such as concrete, aluminum and bare metal.

» MULTISPRAY EVO

MULTISPRAY EVO is a moisture curing one component sealant based on a new generation of sylilated polymers.

MULSTISPRAY EVO may be applied as a seam, by brush or by spray for a perfect OEM sealant match or as a “body” application.

Once applied MULTISPRAY EVO hardens in a short time into a highly elastic and tough seal with excellent barrier properties.

Its major features are:

- It doesn’t change colour after long term external exposure

- Permanently elastic

- Adheres on many surfaces:

Bare and EC metal, stainless steel, painted and primed metal ( for powder paint the application of Primer 1000 is necessary), many composites and plastic materials ( due to the variety of plastic components a preliminary trial is recommended). Will not adhere on PP, PE, TEFLON.

- Good resistance to environmental and chemical agents

MULTISPRAY EVO is applied in many industrial and car body manufacturing units either as a sealant ( joints, hoods, cavities, engine compartment etc..) either as adhesive (applied with notched spatula) for bonding pavements and panels of different materials.

» SP 5

SP5 is a one-component polyurethane adhesive sealant.

It is used in automotive industry for sealing flanges, welded beads and spots in front and back car body , trunk bottom and car floor.

SP5 provides an excellent barrier against water, dust and humidity infiltration in joints and in inside the car. It is resistant to mild chemical agent

SP5 is also used for:

* jointing and bonding in metal construction

* floor-joints subjected to medium low movement

* bonding of vibrating parts in coachworks and containers

» ADVANTSEAL

ADVANTSEAL is a one component SYLILATED POLYMER sealant hardening by reaction with air humidity.

ADVANTSEAL is easy to apply and smooth and has a thixotropic consistency allowing for application in vertical thick layers without sagging. Once hardened it is tough and elastic.

Among the most recommended applications with ADVANTSEAL are : internal and external joint applications, metal flanges and overlaps, gel coat, fibreglass, glass, natural stone, wood and most common plastic ( a preliminary trial in this case is recommended).

ADVANTSEAL is also recommended for elastic bonding between different materials.

The majority of applications will not require the preliminary application of a primer

» 918 RAIL

VABER 918 RAIL is a water based sprayable coating designed to dampen noise from metal vibration.

VABER 918 RAIL is recommended for use in passengers wagon, floors, engine or equipment rooms, canalizations.

Applied on vibrating area at a thickness ranging from 1,5 to 4 mm (dry film),

Vaber 918 RAIL rapidly dries on surface and after 7-14 days in all its thickness.

Once hardened VABER 918 RAIL shows excellent sound damping properties in relation to a very low weight / area ratio.

It strongly dampens sound generated by metal vibration thanks to its viscoelastic properties and excellent adhesion on metal.

VABER 918 RAIL adheres on untreated metal sheet (previously treated with antirust primer), galvanized metal stainless steel, aluminum, GRP (apply not in direct contact with water).

VABER 918 RAIL is classified M1 F1 in compliance to standard AFNOR NF F 16 - 101.

VABER 918 RAIL may therefore be applied as internal coating or on exterior floors of the carriage to reduce noise from vibrating metal.

It dampens noise generated in a wide range of vibrating frequences.

In case of external application VABER 918 RAIL, once hardened, must be painted (with epoxy, PU or acrylic two component paints) for protection against stone and ice chip and to avoid water absorption.

For technical dates refer to technical data sheet.

» SWS

SWS - STOP WATER STRIP is a butyl adhesive tape recommended for sealing different materials such as degreased metal ( primed and galvanized), glass, wood, plastic, ceramic from moisture, water and dust.

SWS - STOP WATER STRIP works in a wide range of temperatures while remaining flexible at low temperatures and maintains good cohesive properties at high temperatures.

» 921 RAIL

VABER 921 RAIL is a water based sprayable coating designed to dampen noise deriving from metal vibration at very low temperatures (-20°C) in passengers wagons, floors, engine or equipment rooms, airduct.

Applied on vibrating area at a thickness ranging from 1,5 to 4 mm (dry film), Vaber 921 RAIL rapidly dries at room temperature into a flexible coat.

Once fully cured it shows excellent flexibility at very low temperature where the majority of other paints break.

Therefore its sound damping properties and stone chip resistance at - 20°C are very good.

VABER 921 RAIL has a high viscosity: it can be applied in thick vertical layers or underbody without sagging or dripping.

Vaber 921 RAIL is classified M1 F0 in compliance to standard AFNOR NF 16-101

VABER 921 RAIL may applied as internal coating or on exterior floors of the carriage to reduce noise from vibrating metal in a wide range of frequencies.

When applied on exterior surfaces it is recommended to protect the product from excessive water absorption with an elastic low temperature paint.

» 240/240 Z

240 is a preformed mastic in loaves, grey coloured.

It's used for sealing cables passages, holes and cracks of big dimension too.

It adheres on any kind of surfaces remaining permanently plastic.

240 Z is a preformed mastic in loaves, black coloured.

It's used for sealing cables passages, holes and cracks of big dimension too.

It adheres on any kind of surfaces remaining permanently plastic.

» SCP 26 RAIL

SCP 26 is a water based sprayable coating designed to dampen noise from metal vibration in passengers wagons, floors, engine and equipment rooms, canalizations.

Applied on vibrating metal area, SCP 26 rapidly dries on surface and after 7-14 days in all its thickness. Once hardened SCP 26 shows excellent sound damping properties and stone chip resistance, has excellent adhesion on bare and painted metal and good resistance to outdoor climates. It can be applied in thick vertical layers without sagging or dripping.

SCP 26 is a fire resistant material certified for application in railway market.

SCP 26 is applied as internal coating or on exterior floors of the carriage (train and bus) to reduce noise from vibrating metal in a wide range of frequencies at different temperatures.

» BURSHABLE 737

BRUSHABLE 737 is a solvent based thixotropic sealant for seams and flanges to be applied by brush or bead.

It may be applied to the flanged or welded metals in front and rear parts of car body, baggage compartment, floor area and the interior floor pan area.

BRUSHABLE 737 dries in a short time and may be accelerated in the oven. Once hardened it will not crack and provides an excellent barrier against water or humidity infiltrations.

» BARRIER PAINT

VABER BARRIER PAINT is a water based intumescent paint for the protection against fire or metal panels and structures.

The special intumescent raw materials start recting when the temperature of the paint surpasses 250°C generating an insulating foam that protects the metal structure form fire for a certain period of time, thus avoiding the collapse.

The Barrier protection time is indicated in minutes and defines the class of the product.

The class is a a function of the support and of the thickness of the applied Barrier Paint.

» AVIATION

MÄDER has operated in the Aeronautics sector for over 25 years, developing unique expertise in high-technology paint, satisfying the most stringent specifications at the request of sector industrial firms, designers and manufactures of components and subassemblies.

MÄDER's aim is therefore to listen to the needs of industrial firms in the sector and create an R&D "task force" dedicated to innovation needs. The technologies developed are without CMR substances and are mainly water-based: the majority of applications and solutions developed have very low VOC emission.

Mäder has SAFRAN, UTC, THALES, EUROCOPTER qualifications, ISO 9001, NF EN9100 and ISO 14001 certifications and is a global partner for all Aeronautical equipment and other manufacturers. Over and above specific studies for each firm, MÄDER is involved with several industrial partners in the ASTECH aerospace centre PHIACRE project financed by the FUI (Inter ministerial development fund) and CEEVO (Val d'Oise Economic Expansion Committee).

MÄDER is also a partner of the HARMONY EIS, offering test resources including specific forms of surface treatment. The international distribution of products (outside France) has been entrusted to INTERTURBINE AVIATION LOGISTICS for the MRO markets.

» 230/1B

230/IB is a butyl based sealer with good characteristics of adhesion, cohesion and elasticity.

It's mainly used in building industry for sealing aluminium and glass casing, where is necessary resistance to water and air passage.

Thanks to its adhesion and good E-modulus, it absorbs excellently thermal expansion of the structures.

230/IB is also used for sealing box-type parts, sheet junctions, EPDM seals, etc.

» PLATE GLASS & COSMECTICS

When the beauty of the object combines innovation in its colour and material...

MÄDER proposes an extended range of products for architectural plate glass and small bottles, with gloss and mat varnishes, pigmented and colouring bases, solvent-based or water-based, on which serigraphy can be applied without flame treatment, enabling each industrial company to make up its own shades or call upon our skills to make specific, ready to use shades.

In partnership with a recognised operator in the field of metallic coatings, we offer a complete range of undercoats and finishing varnishes, cross-linked using an oven or UV.

All these ranges of products are developed jointly by our teams based at our sites in Europe, which enables us to offer an extensive range that can satisfy all application conditions and specifications.

Partners and suppliers to prestigious perfume houses, our product range also includes packaging: cosmetics, plastics, drinks and medical applications, via its many innovations.

» AUTOMOTIVE

The Mäder Group is world leader in paint and varnish for application to plastics and develops ranges of innovative, environment-friendly products.

- Interior decor: Special-effect decorative and harmony shades in solvent and water-based versions

- Exterior decor: Specific solutions for roof bars, handles, rear-view mirrors, trims, radiator grills, etc.

- Steering wheels: Mould-coating and post painting technology

- UV finishes: Colourless and tinted, satin or shiny varnish for scratch resistance and energy saving in high-temperature drying.

- Finishes for metal: A choice of pearl or aluminium finishes and combinations

- Services: Associated techniques, a Design department and technical support

» ACUPOL

Thermal and acoustic material. Made by sinthetic fibres, bonded by thermoplastic binder, available in different colour black, White and green.

Atoxic material, non irritant, 100% recyclable.

Sound proofing material, for flat and moulded part, interior and engine compartment.

Suitable for sound absorption, in the Automotive Industry, Train Industry, Household appliances, Building and construction.

Upon request, is available with technical fabric, microperforated and flat aluminium foil esthetic fabric in various colour, self adhesive in one or two side.

TECHNICAL FEATURES

• Density: From 10 to 100 kg/m2

• Thickness: From 5 to 120 mm

• Thermal Conductibility: 0.036 W/mk

• Working Temperature: From - 40 up to 110 °C

Fire Resistance:

• Euroclass - EN 13501: 2002 Class B x fire - S1 x smoke, drop no. d0

• Euroclass - UNICEI 11170 - CEN/TS 45545 - 2 : 2009 Hazard Levels HL1 - HL2 - HL3

» ELECTRO TECHNICAL

This range of products is a direct continuation of the integration of the Mäder Group into the design of and innovation for resins entering into the formulation of varnishes and paint for Electro technical use.

The market for varnish and paint for Electro technical use is a market segment covering insulation supplies for production, distribution and electrical equipment, as well as electrical engineering machines and systems for industry.

This market is split into four Business Lines, as follows :

- Primary insulation varnish

- Secondary insulation varnish and paint and varnish for insulation film

- Resins for coating electronic components and transformers

- Impregnation varnish for magnetic sheet metal

» PRORUBBER

Flexible polymeric viscoelastic barrier damping and barrier material. Made with a mix of plastic component with fillers, non irritant, 100% recyclable.

Heavy barrier material for acoustical insulation, could be also laminated with sound absorbent material as a typical element for sound solution.

With pressure sensitive adhesive as an antivibration pad.

Standard products available with aluminium foil, upon request, is available with technical fabric, microperforated and fabric in various colour, self adhesive in one or two sideation pad.

TECHNICAL FEATURES

• Density: gr. 2,0 cm3

• Thickness: From 1,3 to 6 mm

• Weight: From 2,0 kg/mq to 10 kg/mq

• Working temperature: - 40 to 110 °C

Fire resistance:

• Euroclass - EN 13501: 2002 Class B x fire - S2 x smoke, drop no. d0

• Euroclass - CEN/TS 45545 - 2:2009 Hazard Levels HL1 - HL2 - HL3

» HIGH TEMPRATURES

MÄDER designs paint to coat inserts and fireboxes that withstands constraints affecting shades, adherence and protection capability in extreme temperatures, up to a peak of 650°C.

These products are available in solvent-based, high dry extract and water-based versions to meet the requirements of all the industrial firms in the sector.

» MARINE

MÄDER makes its technology and know-how available for yachting professionals and amateur enthusiasts, in close collaboration with constructors for woodwork varnish, and in partnership with the brand OCEOPROTEC for anti-fouling coating.

For years, MÄDER has been creating very high-quality finish paints for the automotive and aeronautics industries, and now that know-how has been applied to a range of Yachting paints under the brand MÄDER Marine with a range of OCEOPRIMER, OCEOCOLOR, OCEOWOOD and EPOSURF. These products represent the very essence of MÄDER expertise in terms of quality and durability, while at the same time providing applicators with major productivity gains.

Particularly in the fields of high-durability single-component glycerophtalic and bi-component polyurethane finish paints, MÄDER offers a unique and innovative concept of tinting machines that enables us to provide a range of more than 60 dedicated sailing colours, and more than 3,000 RAL and NCS colours. A simulation software allows applicators to choose from these colours and different applications, to create and compose their paint application, and to simulate this visual effect on the hulls of boats.

MÄDER, the designer of a permanent, non-erodible anti-fouling paint application system, recently acquired the brand Oceoprotec.

Thanks to a network of approved applicators, MÄDER is able to offer a range of products for hull protection – Oceoprotec anti-fouling and Oceoseal anti-osmosis – based on a technology that is 100% waterborne and VOC-free.

Oceoprotec is an organometallic coating with anti-fouling properties, providing permanent protection for hulls, intended to prevent marine organisms from becoming attached to boat hulls. The aim is to prevent the colonisation of hulls by microorganisms and the growth of a plant bio film, the presence of which considerably slows down boats and proportionately increases their fuel consumption.

Once reticulated, the coating becomes an inert, non-erodible film which is non-polluting for the seabed.

In contact with water, the electrically charged copper ions (Cu2+) seek particles of opposite polarity, such as bacterias, viruses and fungi. In contact with this ionic field, the microorganisms are neutralised and they escape or transform into a deposit of silt/bio film which can be eliminated manually simply by wiping, or mechanically once the boat is moving.

The coating’s hardness and its very low roughness coefficient cause a major reduction in the friction coefficient, contributing to a notable increase in speed, manoeuvrability, and up to 25% in fuel savings, in turn producing a reduction in energy consumption for a dual economic and ecological gain.

The Mäder Marine range :

- Protection and Finishing of Boats: Oceoprimaire + Ocecolor

- Protection and Finishing of woodwork and boat decks: Oceowood + Oceodeck

- Anti-corrosion Protection: Oceoantico

- Anti-fouling Protection: Oceoprotec

- Anti-osmosis Protection, preventive and remedial: Oceodry + Oceoseal

» GAS

A historic market for MÄDER, our range of products covers all applications to protect storage tanks and bottles of all sizes.

Validated by the French butane and propane federation, the CFBP, our product ranges are certified by the Pourquery laboratories according to the standards applicable to above and below-ground storage.

» ANTICORROSION & OFF SHORE

From high external durability systems to off-shore systems.

MÄDER has developed a complete anti-corrosion and finishing coat range that guarantees extended use of all your equipment.

Thanks to the coordination of the R&D resources of our various production sites in Europe, MÄDER has established a highly efficient range of products for each type of purpose, with certification awarded by external organisms and laboratories such as the Pourquery laboratories.

» AGRICULTURAL & PUBLIC WORKS EQUIPMENT

Present in the sector for 25 years now, we develop single and dual-component paint systems, solvent or water-based, that meet the very strict specifications of the sector.

Very efficient in terms of anti-corrosion and exterior durability, our various paint systems come in all the shades specific to manufacturers, and, at the same time, we offer a service to supply all their subcontractors.

» COIL COATING

With a long experience in this business, Mäder offers high quality coatings made of Polyester/Melamin or Isocyanate resin, highly flexible, scratch resistant, with a good weatherability, destined for Architecture (cladding, jalousie, garage doors…), roofing, household appliance, furniture industry…

These products are available in a wide range of colors, in particular with metallic or chrome effects.

» FOUNDRIES / WIND POWER

High performance coatings for wind energy equipment and foundries.

To meet customer demand at its best, we offer a wide range of products with corrosion resistance, weatherability , conventional or water based dipping paints, one component or two component, oil-resistant.

» PIPELINE

Mäder offers in this business a wide range of products for ductile iron pipes, fittings and armatures on bituminous, PUR or epoxy base.

Our product portfolio is certified for the contact with potable water and are referenced in the leading word wide pipeline manufacturers..

» RESERVOIRS & TANKS

In this sector of activity, MÄDER proposes coatings specially developed to meet international standards governing anti-corrosion, protection for the insides of tanks, hydrocarbon water separators, renovation of retention tanks and reservoirs for petrochemical installations, waste water treatment plants and water towers with paint systems highly resistant to waste water and hydrocarbons.

Backed by certification and approval from the Institut Pasteur Lille, a range of epoxy resin coatings is available, approved for hot and cold drinking water use.

ADISA, a Group subsidiary, also offers onsite implementation of multi-coat renovation systems.